| CALL US NOW!

Hi-Build True Water Based Urethane Epoxy 100% Solids - Zero VOC

The Hi-Build Epoxy combines durability and high chemical resistance with flexibility in its application.

Adhesion

Abrasion

5 Solution In One Product

Sustainable & Green

5 Products In 1

Impact Resistance

Hardness

Flexibility

BOLT COATINGS HI-BUILD EPOXY TECHNOLOGY

The technology behind the Hi-Build allows for making an epoxy coating that has Zero VOCs, is virtually odorless, has low viscosity (98 KUs) and without using solvents or other hazardous materials.

APPLICABLE SUBSTRATES & LOCATIONS

• VCT • Patient Rooms • Hallways

• Vinyl Sheeting • Kitchens • Cafeterias

• Terrazzo • Restrooms • Showers • Concrete • ER’s • Offices

• Tile&Grout • Lobbies • Entrances • LVT • Dialysis Centers

• Clinics • Metal • Acute Hospitals • Nursing • Wood

• Outpatient Centers • Urgent Care

KEY FEATURES & BENEFITS

• Zero VOCs

• Virtually Odorless

• No Out-Gassing–Spike Back Roller

• One Product Replaces Three – Fills Cracks, Spalled

Concrete & Self Priming

• Direct to Concrete, Metal, Wood & Fiberglass

• Resistant to Abrasion, Strong Chemicals & Acids

• Achieves a Hard, Smooth, High Gloss Surface

• Easier to Clean & Disinfect

• High Gloss Improves the Effectiveness of

Available Lighting

• Easy Application with Rollers or Squeegees

• Can Be Used in a Flake or Quartz Broadcast System

• Available in Clear or Custom Colors

Solutions For Concrete Applications

There is more concrete in the world than any other substrate. But why is it that the technology for coating concrete floors is so outdated and costly? Systems must include epoxy primers, epoxy intermediate coats followed by a polyurethane top coat for overall protection.

What if you were able to eliminate the primer sand intermediate coats and just use a polyurethane direct to the concrete?It is un heard of due to the solvents in polyurethanes causing reactions with the concrete.

A solution is out there! Bolt Coatings is a proven a water-based, without the use of a solvent or co-solvent, aliphatic polyester polyurethane technology.

Chemical Resistance

PROVIDES EXCELLENT RESISTANCE TO ALL TYPES OF CHEMICALS KETCHUP, MUSTARD, ALCOHOL, ETC…

UV/Corrosion Resistance

MINIMAL GLOSS LOSS OR COLOR FADE – DIRECT WITHOUT PRIMERS – PROVEN IN ALL TYPES OF ENVIRONMENTS

Breathable

WATER BARRIER NOT VAPOR BARRIER – ALLOWS WATER VAPORS TO MIGRATE THROUGH THE COATING

Repairable

EASILY REPAIRABLE IN THE FIELD – SELF LEVELING ALLOWS REPAIRS TO SMALL OR LARGE SECTIONS

Easy To Maintain

DIRT, DEBRIS, MILDEW AND SOAP SCUM SIT ON TOP OF COATING AND ARE EASILY REMOVED

Slip Resistance

INCREASES THE SLIP RESISTANCE CERTIFIED “HIGH TRACTION” BY NFSI

Protects Substrate

MAKES THE SUBSTRATE LAST LONGER – ANY SCRATCHES GO INTO THE COATING NOT SUBSTRATE

No Prop 65 Chemicals

Which are known in CA to cause Cancer

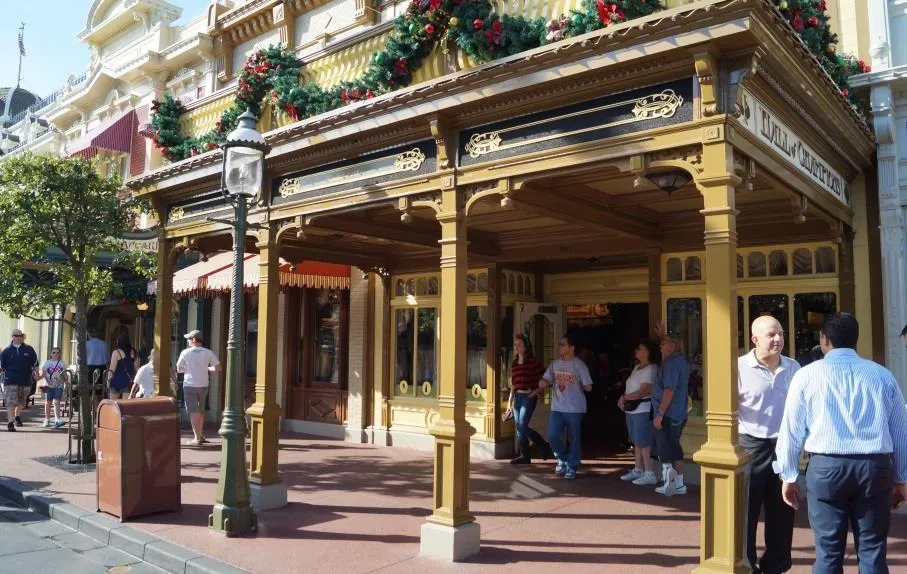

Customer Success Stories

Walt Disney World – Main Street USA

& Splash Mountain

Location:

Orlando, Florida

Product:

Gloss Clear & Satin Clear

Substrate:

Metal & Concrete (Previously Painted Surfaces)

Product Volume Applied:

~100 gallons

Unique Attributes of Project:

The Clear coatings were applied to protect the underlying paint and make it last longer.

Post Application Comments:

The senior spec writer for Walt Disney, stated that, “Hand oils, sweat and sunscreen have no affect on these coatings. The increased abrasion resistance protects against the constant human contact to the coated areas.”

Walt Disney World – ESPN Wide World of Sports

Location:

Orlando, Florida

Product:

Gloss Green

Substrate:

Metal

Product Volume Applied:

~160 gallons

Unique Attributes of Project:

High profile, signature application that required coating all metal gates at the facility.

Post Application Comments:

Gloss was applied to ensure that all gates maintained a like-new appearance and withstood wear and tear from people traffic, industrial cleaning / equipment, and the intense Florida weather (the prior product faded).

Universal Studios – The Wizarding World of Harry Potter

Location:

Orlando, Florida

Product:

Gloss White

Substrate:

Urethane Foam (Snow)

Product Volume Applied:

~60 gallons

Unique Attributes of Project:

High profile, signature application at Universal Studios that encompassed coating the rooftop snow; required product mixing and hoisting to scaffolds for application.

Post Application Comments:

The Gloss was applied to ensure that the snow did not yellow from the intense Florida sun (the prior product yellowed). After more than 24 months since application “the snow is as white as it was on the day of application.”

US Cellular Field – Home of the Chicago White Sox

Location:

Chicago, Illinois

Product:

Satin Clear

Substrate:

Split Face Block

Product Volume Applied:

~160 gallons

Unique Attributes of Project:

US Cellular wanted a coating that was high performance and gave them anti-graffiti characteristics. The Satin Clear also enhanced the color of the split face block substrate.

Post Application Comments:

The application was applied the summer of 2012 and is not only protecting the surface from graffiti but also protecting the surface from UV damage.

RMS Queen Mary - Smokestacks

Location:

Long Beach, California

Product:

Gloss Red / Black

Substrate:

Metal

Product Volume Applied:

~125 gallons

Unique Attributes of Project:

Coating the three iconic smokestacks of the world famous HMS Queen Mary - - visible from 20 miles away!

Post Application Comments:

The Queen Mary operator selected the Gloss for its industry leading combination of ultra-durable performance and ultra-low VOC levels. The City of Long Beach & the SCAQMD made a special commendation to the operator for its environmentally friendly coating selection.

Save Thousands in Vandalism clean up/Graffity removal!

Simple Spray Away

"Defend Your Walls: Bolt Coatings - Graffiti's Worst Enemy"

"Discover Bolt Coatings, the ultimate graffiti-resistant solution powered by our proprietary Polyurethane technology! As a Prop 65 compliant, environmentally friendly formula, we're committed to safeguarding both your walls and the planet. Choose Bolt Coatings – Graffiti's Worst Enemy and Earth's Best Friend!"

Contact Us Today To Get Started!

Book a hassle free demo of our product with no strings attached.

FAQ

Is Bolt Coatings Water Based

Yes, We are a true water based system produced in water with no solvents.

Is Bolt Coatings Eco Friendly

Yes, we are low to Zero VOC's, Less than 20 G/L

Is our solution odorless

Yes we are virtually odorless and leave no lingering smells

Are we Prop 65 Compliant

Yes, we use no Prop 65 chemicals, which are known in the state of CA to cause cancer.

Do we meet USGBC

Yes, Bolt Coatings meets USGBC Leed criteria to obtain Leed credits.

Does Bolt Coatings require special applications

No, Bolt Coatings does not require special application equipment or require respirators.